The whole world of Panel Processing machines

The whole world of Panel Processing machines

The whole world of Panel Processing machines

The whole world of Panel Processing machines

A precision m/c @ lower investment & operational cost, which improves your production, quality & profitability...

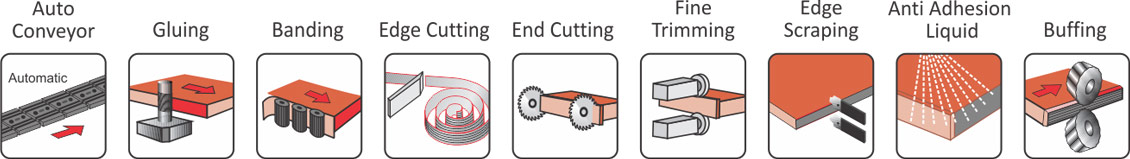

The Feed Track :

Robust feed chain & conveyor system with German gearbox gives straight movement & effective pressure on small / big panels.

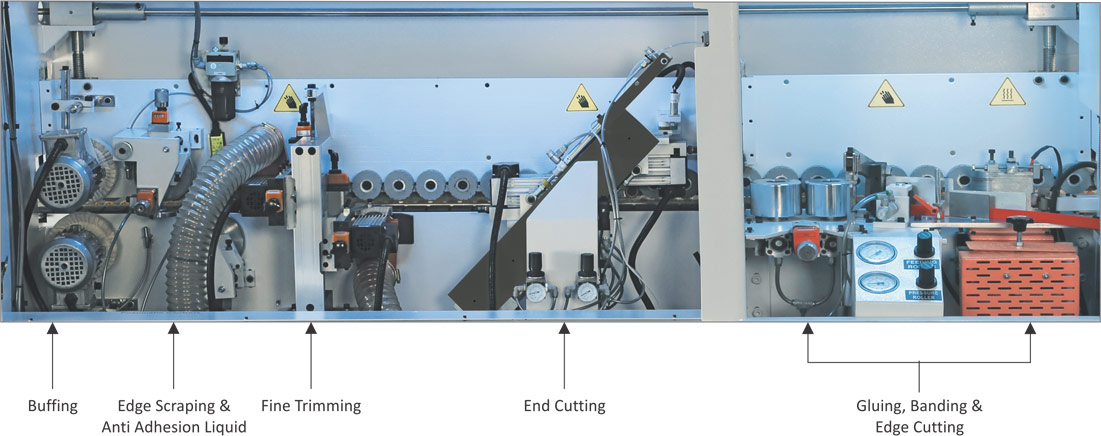

Gluing, Banding & Edge Cutting :

Glue spreading roller provides precise & consistent glue application.

Perfect adhesion to the applied edge with 2 heavy duty pressure rollers actuated by pneumatic cylinders.

Heavy duty knife with pneumatic pressure cuts the edge banding materials up to 50 mm height & 3 mm thickness.

End Cutting :

Compact and powerful high frequency two independent motors guarantees best finish on edge, sliding on two prismatic guideways with recirculation ball bearings.

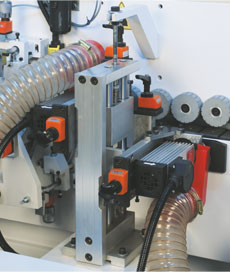

Edge Fine Trimming :

Compact and powerful high frequency two motors guarantees best finish on edge.

Trimmer 2R cutter for PVC/ABS gives perfect rounding on edge of straight panel.

Edge Scraping & Anti Adhesion Liquid :

Gives the best finishing touch to the PVC/ABS edges , leaving no trimming marks on the panel.

Unit complete with rotating copiers.

In order to prevent glue to adhere on panel, this liquid is sprayed to lower & upper edge surface of the panel.

Buffing :

Independently adjustable buffing wheels, for cleaning & polishing of the panel edges.

Control Panel :

Easy accessible user friendly control panel positioned at machine in-feed, for easy & quick operations.

| Model No | Unit |

J-4750.in |

| Work piece thickness range | mm |

10 - 50 |

| Minimum work piece width | mm |

120 |

| Minimum work piece length | mm |

150 |

| Edge Banding Thickness for PVC & ABS in coil form | mm |

0.4 - 3.0 |

| Workpiece Feed | m/min |

11 |

| End cutting motor power | no / hp |

2 x 0.5 |

| Fine Trimming motor power | no / hp |

2 x 1 |

| Buffing motor power | no / hp |

2 x 0.5 |

| Air pressure required | kg/cm2 |

6 to 7 |

| Working temperature range | °C |

180 - 200 |

| Glue pot capacity | kg |

2 |

| Total power | hp |

8.5 |

| Machine dimension (L x B x H) | mm |

3350 x 950 x 1485 |

| Approx net weight | kg |

1200 |