The whole world of Panel Processing machines

The whole world of Panel Processing machines

The whole world of Panel Processing machines

The whole world of Panel Processing machines

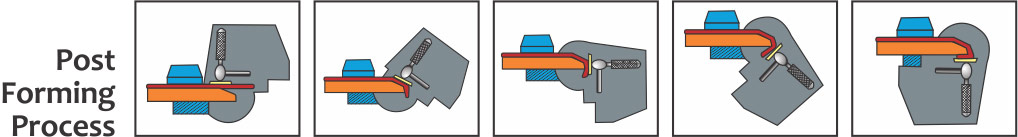

PLC based control panel as standard feature with capacity of 10 programs

Special Pneumatic gauge is operated by 2 pneumatic cylinders for repetitive jobs' setting

8 - Pneumatic cylinder panel with heater bar to apply uniform pressure on work piece for effective bonding of laminate.

Pressure Clamp working with 3 pneumatic cylinders & having rubber pad for better grip on work piece and to avoid damage to it while clamping.

Separate Electronics & Pneumatic compartments for easy accessibility and maintenance.

| Model No | Unit |

J-2400.in |

| Max. length of work piece | mm/feet |

2440 / 8 |

| Min. length of work piece | mm |

600 |

| Work piece thickness range | mm |

16 - 105 |

| Min. work piece width | mm |

200 |

| Max. heating temperature | degree |

200 |

| Compressed air requirement | hp / kg-cm² |

2.0 / 7 |

| Heating element | kW |

2.4 |

| Electric motor - 3 phase | hp |

0.5 |

| Total Power | hp |

3.7 |

| Machine dimensions (L x B x H) | mm |

3300 x 1000 x 2000 |

| Approx. net weight | kg |

1000 |