Redefining Panel Processing Technology

Redefining Panel Processing Technology

Redefining Panel Processing Technology

Redefining Panel Processing Technology

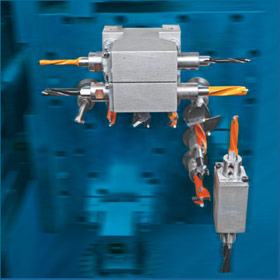

V8H6 Boring Unit

8 Vertical drilling spindles

4 Horizontal drilling spindles in X-direction

2 Horizontal drilling spindles in Y-direction

Grooving saw in X-direction

Heavy Duty Routing Spindle

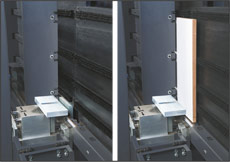

Workpiece clamping device

Easy adjustment of the clamping device (manually) to the workpiece thickness (clamping device stroke 10 mm).

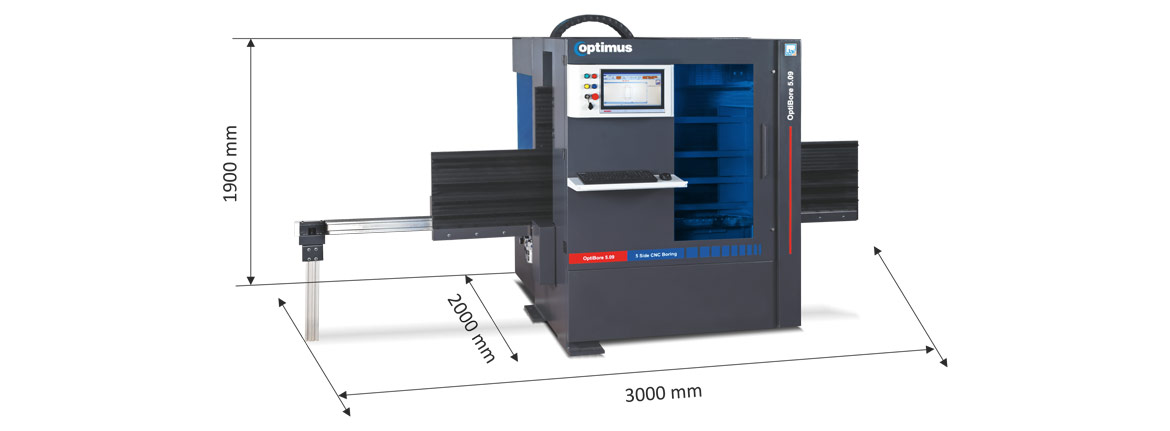

Workpiece load area

Mechanical support with roller conveyor in the loading area of the machine

Working Length :

Extension from 2500 to 3050 mm

Fast and intuitive operation thanks to simple, direct navigation

Select from a choice of variables for flexible variable programming

Quickly create individual subprogram

| Control system | 15” PC with Beckhoff Control System | |

| Work piece processing size | Panel length - max. / min. | 2500 / 200 mm |

| Panel width - max. / min. | 850 / 70 mm | |

| Panel thickness - max. / min. | 60 / 12 mm | |

| Maximum positioning speed: | X - Axis | 25 m / min |

| Y - Axis | 25 m / min | |

| Z - Axis | 15 m / min | |

| Boring & Grooving unit : | Vertical drilling spindles | 8 no |

| Horizontal drilling spindles | 4 (X-Direction) no | |

| 2 (Y-Direction) no | ||

| Tool shank diameter | 10 mm | |

| Grooving saw diameter - X (Axis) | 120Ø mm | |

| Motor power | 2.2 kw (3 hp) | |

| Routing unit spindle : | Router spindle power | 6 kw (8 hp) |

| Spindle speed | 18000 rpm | |

| Spindle collet | ER 32 | |

| Other specifications : | Dust Extraction Port | 150Ø mm |

| Compressed Air Pressure | 7 bar | |

| Total power | 12.5 kw (16.7 hp) | |

| Machine dime. (L x B x H) | 3000 x 2000 x 1900 mm | |

| Approx. net weight | 1600 kg |