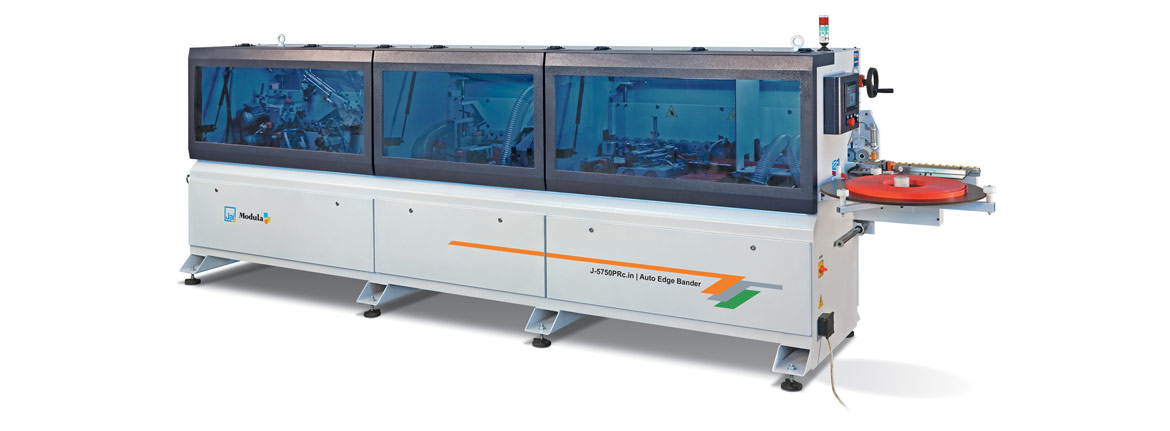

The whole world of Panel Processing machines

The whole world of Panel Processing machines

The whole world of Panel Processing machines

The whole world of Panel Processing machines

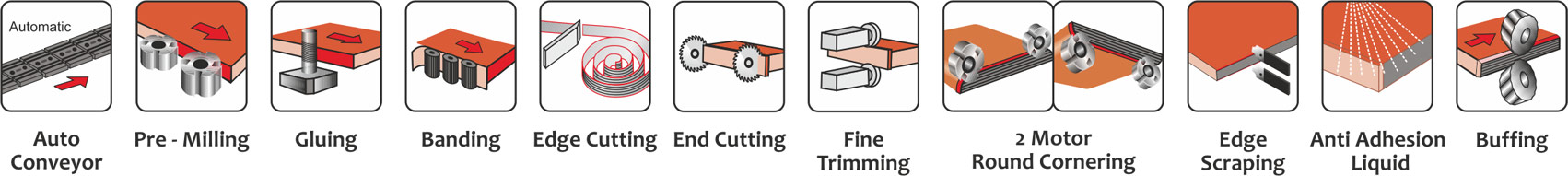

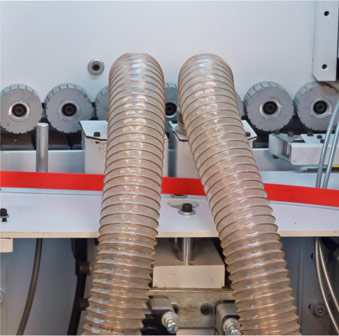

Pre-Milling :

An optimal unit for panel edge pre-milling with two high frequency compact motors. Diamond cutters are standard supply with the machine.

Individual pneumatic cylinder for perfect prepares the panel for gluing. Smoothes the panel for achieving perfect joint line of the edge.

The Feed Track :

Robust feed chain & conveyor system with German gearbox gives straight movement & effective pressure on small / big panels.

Gluing, Banding & Edge Cutting :

Glue spreading roller provides precise & consistent glue application.

Perfect adhesion to the applied edge with 3 heavy duty pressure rollers actuated by pneumatic cylinders.

Heavy duty knife with pneumatic pressure cuts the edge banding materials up to 50 mm height & 3 mm thickness.

Edging wooden strip up to 10 mm

End Cutting :

Compact and powerful high frequency two independent motors guarantees best finish on edge, sliding on two prismatic guideways with recirculation ball bearings.

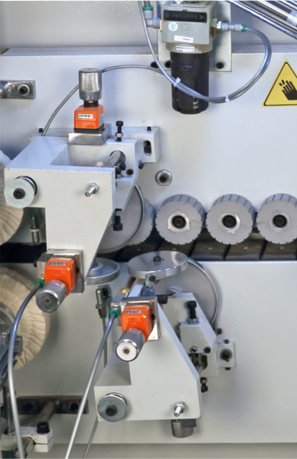

Edge Fine Trimming :

Compact and powerful high frequency two motors guarantees best finish on edge.

Trimmer 2R cutter for PVC/ABS gives perfect rounding on edge of straight panel.

2 Motor Round Cornering :

Compact and powerful high frequency two motors guarantees best finish on edge, sliding on two prismatic guideways with recirculation ball bearings.

Trimmer 2R cutter for PVC/ABS gives perfect rounding on edge of straight, chamfered and regular post formed panel.

Edge Scraping & Anti Adhesion Liquid :

Gives the best finishing touch to the PVC/ABS edges, leaving no trimming marks on the panel.

Unit complete with rotating copiers.

In order to prevent glue to adhere on panel, this liquid is sprayed to lower & upper edge surface of the panel.

Buffing :

Independently adjustable buffing wheels, for cleaning & polishing of the panel edges

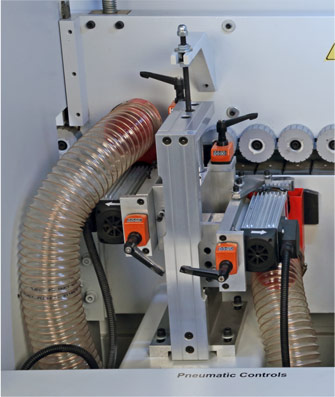

Control Panel :

Easy accessible user friendly Smart Touch PLC control panel positioned at machine in-feed, for easy & quick operations.

| Model No | Unit |

J-5750Rc.in |

J-5750PRc.in |

| Work piece thickness range | mm |

10 - 50 |

10 - 50 |

| Minimum work piece width | mm |

120 |

120 |

| Minimum work piece length | mm |

150 |

150 |

| Edge banding thickness | |||

| - For PVC & ABS in coil form | mm |

0.4 - 3.0 |

0.4 - 3.0 |

| - For Wooden Strip form | Up to 10 |

Up to 10 |

|

| Dual work piece feed | |||

| - For PVC & ABS | m/min |

11 |

11 |

| - For wooden strip | 6 |

6 |

|

| Pre-milling motor power | no/hp |

n / a |

2 x 2 |

| End cutting motor power | no/hp |

2 x 0.5 |

2 x 0.5 |

| Fine Trimming motor power | no/hp |

2 x 1 |

2 x 1 |

| Round Cornering motor power | no/hp |

2 x 1 |

2 x 1 |

| Buffing motor power | no/hp |

2 x 0.5 |

2 x 0.5 |

| Air pressure required | kg/cm2 |

6 to 7 |

6 to 7 |

| Working temperature range | °C |

180 - 200 |

180 - 200 |

| Glue pot capacity | kg |

2 |

2 |

| Total power | hp |

11 |

15 |

| Machine dimension (L x B x H) | mm |

4700 x 950 x 1485 |

5200 x 950 x 1485 |

| Approx net weight | kg |

1600 |

1750 |