The whole world of Panel Processing machines

The whole world of Panel Processing machines

The whole world of Panel Processing machines

The whole world of Panel Processing machines

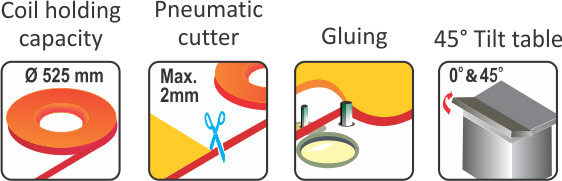

A specially designed hylum surface working table can be tilted from 0° & 45°

A user friendly electro control panel which monitors & controls the operation

The pneumatic cutting device can be set to actuate the pneumatic cutter to cut the band

The glue in the glue pot, glue leveler, wiper, the extrusion screw and the heating element all make a bonding system, which gives an effective & efficient banding to the work piece.

Specially design height adjusting steel roller give perfection to edge band for proper fixing with work piece.

| Model No | Unit |

J-2500.in |

| Table size (L x B) | mm |

1100 x 800 |

| Minimum work piece length | mm |

280 |

| work piece thickness range | mm |

10 - 50 |

| Edge banding thickness for PVC / ABS in coil form | mm |

0.4 - 2.0 |

| Min-Radius for curved Edging | mm |

20 |

| Glue pot capacity | kg |

1.5 |

| Feed speed | m / min |

4 to 12 |

| Front table tilt angle | degree |

0° & 45 ° |

| Front table extension length | mm |

Up to 200 |

| Maximum setting temperature | °C |

180° |

| Compressed air requirement | hp / kg / cm² |

0.5 / 5-7 |

| Heating element | kw |

1.5 |

| Electric motor | kw |

0.37 (415V, 3Ø) |

| Power supply | voltage / Ø |

415V, 3Ø |

| Total Power | hp |

2.5 |

| Machine dimension (L x B x H) | mm |

1750 x 950 x 950 |

| Approx. net weight | kg |

240 |