The whole world of Panel Processing machines

The whole world of Panel Processing machines

The whole world of Panel Processing machines

The whole world of Panel Processing machines

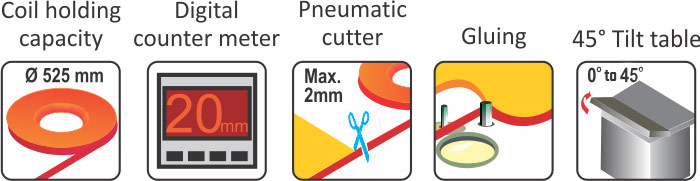

A specially designed hylum surface working table can be tilted from 0° to 45°

A user friendly electro-pneumatic control panel which monitors & controls the operation

The pneumatic cutting device can be set to actuate the pneumatic cutter to cut the band for a pre-defined length using an electronic counter

The glue in the glue pot, glue leveler, wiper, the extrusion screw and the heating element all make a bonding system, which gives an effective & efficient banding to the work piece.

Specially design height adjusting steel roller give perfection to edge band for proper fixing with work piece.

| Model No | Unit |

J-3000.in |

| Table size (L x B) | mm |

1150 x 900 |

| Minimum work piece length | mm |

280 |

| work piece thickness range | mm |

10 - 50 |

| Edge Banding Thickness for PVC & ABS in coil form | mm |

0.4 - 2.0 |

| Min-Radius for curved Edging | mm |

20 |

| Glue pot capacity | kg |

3 |

| Feed speed | m/min |

4 to 12 |

| Front table adjustment (Up & Down) | mm |

3 |

| Front table tilt angle | degree |

0° to 45° |

| Maximum setting temperature | °C |

180° |

| Compressed air requirement | hp/kg/cm2 |

0.5 / 5 - 7 |

| Heating element | kw |

1.5 |

| Electric motor | kw |

0.37 (415V, 3ø) |

| Power supply | voltage / ø |

415V , 3ø |

| Total Power | hp |

2.5 |

| Machine dimension (L x B x H) | mm |

1850 x 1000 x 1040 |

| Approx. net weight | kg |

280 |

Note : Single phase machine available on request