Wood is in Our Blood , Wood is Our World

Wood is in Our Blood , Wood is Our World

Wood is in Our Blood , Wood is Our World

Wood is in Our Blood , Wood is Our World

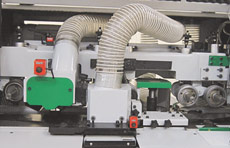

Sturdy built heavy-duty machine to suit Indian working condition for precise application of four side operation in one pass.

Use for mass production of door frames, window frames,wooden floors.etc.

Separate motors for each spindle to ensure efficent power transmission.

Powerfull drives for the cutter blocks delivers high torque for heavy duty cutting requiremens.

Top feed rollers for easy feeding of work piece with variation in thickness.

Bed lubrication to reduce friction and improve feeding of timbers.

Sealed safety enclose to reduce noise levels, improve extraction and operator safety.

All spindles are adjustables and their key devices are positioned on front of the machine for convenience.

Feed rollers are driven through gearbox to give smooth feeding. Power drives for all spindles for heavy duty cutting requirements.

Specifications |

Unit |

J-4423 |

| Working width min / max | mm |

25 / 230 |

| Working thickness min / max | mm |

8 / 120 |

| Feeding speed | m/min |

6 to 12 |

| Top & bottom spindle cutter dia | mm |

120 Φ |

| LH & RH spindle cutter dia min / max | mm |

100F / 180 Φ |

| Spindle shaft dia | mm |

40 Φ |

| Top & bottom spindle cutter motor | hp |

7.5 / 5.0 |

| LH & RH spindle cutter motor | hp |

5.0 / 5.0 |

| Feeding motor | hp |

3 |

| Feed beam up-down motor | hp |

0.5 |

| Air pressure required | kg/cm² |

5 to 7 |

| Total power | hp |

26 |