The whole world of Panel Processing machines

The whole world of Panel Processing machines

The whole world of Panel Processing machines

The whole world of Panel Processing machines

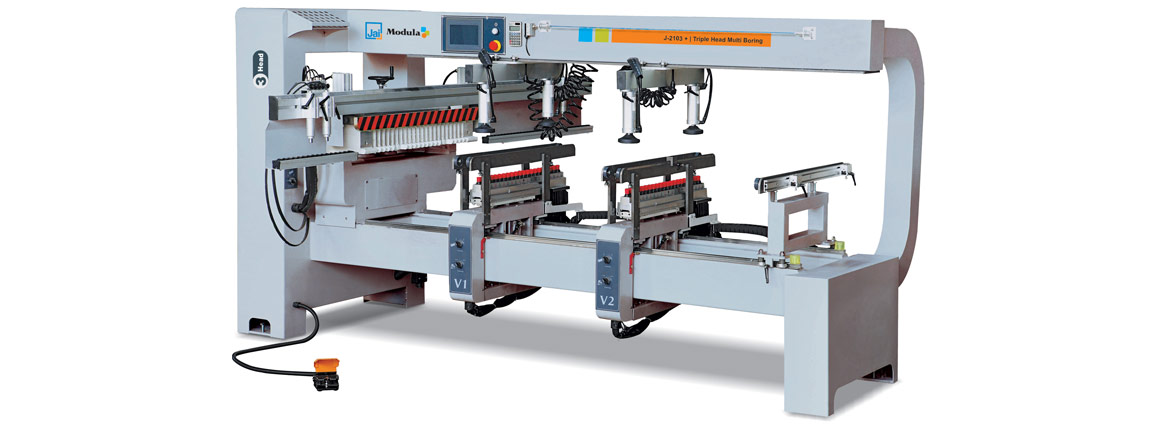

The two vertical heads can slide away one by one on rolling guides from each other.

The aluminum fence has four reference stops that slide on support rollers for smooth positioning. This makes it easy to feed long work pieces.

Quick adjustment & easy setting of horizontal boring head unit. Boring depth can be also easily adjustable. Unit has pneumatically operated solid clamp for proper clamping of work piece at front end during boring process.

User friendly smart touch PLC control panel for Quick, precise & easy setting - up.

| Model No | Unit |

J-2103 + |

| Max. working thickness | mm |

60 |

| Max. size of workpiece | mm |

1850 x 640 |

| No. of spindle head | no's |

Three |

| No. of spindles per head | no's |

21 |

| Total spindles | no's |

21 + 21 + 21 = 63 |

| Minimum center distance between 2 vertical heads | mm |

150 |

| Maximum center distance between 2 vertical heads | mm |

1650 |

| Shank diameter of drill | mm |

10 |

| Drilling depth | mm |

0 - 50 (drill length 70 mm) |

| Air pressure required | kg/cm2 |

6 to 7 |

| Elect. Motor / Total Power | no/hp |

3 x 2 = 6 |

| Machine Dimensions (L x B x H) | mm |

3000 x 3050 x 1500 |

| Approx. net weight | kg |

900 |