Redefining Panel Processing Technology

Redefining Panel Processing Technology

Redefining Panel Processing Technology

Redefining Panel Processing Technology

Precision top drilling unit

Vertical : 7 (X axis ) + 5 (Y axis )

Horizontal : 2 (Left ) + 2 (Right) and 2 (Front) + 2 (Back)

Precision bottom drilling unit

Vertical : 9

Top & Bottom Router Spindle

2 x 3.5 kw (5 hp), 18000 rpm

Automatic clamping and feeding device

Auto side aligner position the board from the side tightly to ensure precise gripping.

Air floating table to avoid scratches on board and assuring smooth board movement, suitable for heavy and big panels.

High torque helical gear reducer

Automatic lubrication system circulates lubrication to the required parts of the machine, ensures efficient operation and increase life of parts

Control system : SNYTEC CNC system

1. Can compat with any brand Design software

2. Processing files (dxf, CAD, mpr, ban, xml, ingo, dwg format etc.,) auto uploaded by scanning bar code or 3D drawing and generating NC program for processing.

Horizontal drilling bits process four side holes

Top & Bottom vertical drilling bits process top side & bottom side vertical holes respectively on panel

Cutting, routing and top - bottom grooving process on panel.

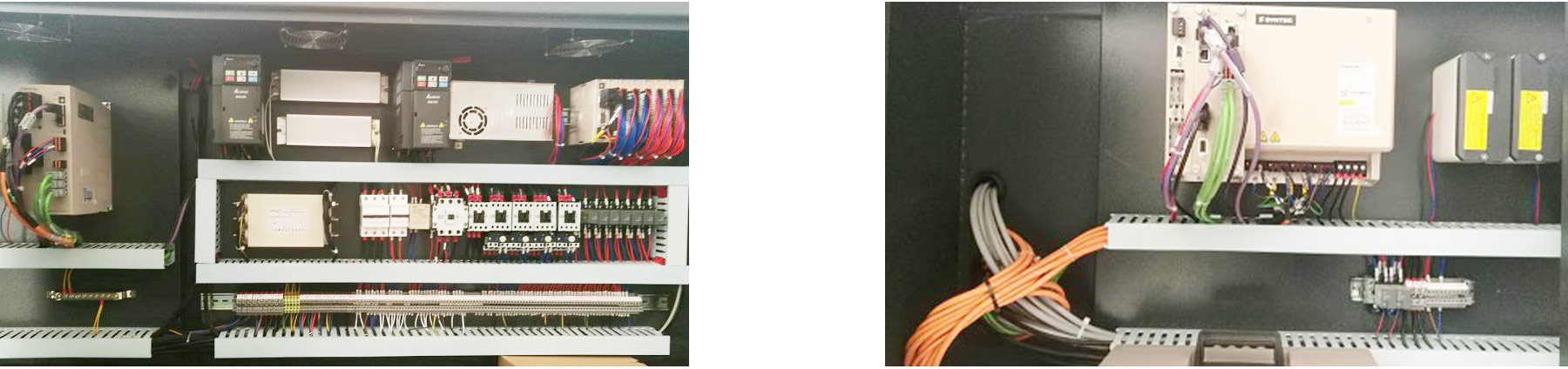

All electrical & electronics components are well known international reputed brands for trouble free performance.

| Model | OptiBore 6.12 |

||||||||||

| Control system | 21" PC with syntec control system | ||||||||||

| Work piece Processing size | Panel width - max. / min. | 1200 mm / 50 mm | |||||||||

| Panel length - max. / min. | 5000 mm / 250 mm | ||||||||||

| Panel thickness - max. / min | 48 mm / 12 mm | ||||||||||

| Axis travel & maximum positioning speed : | X & U - Axis | 5000 mm & 130 m / min | |||||||||

| Y - Axis | 1680 mm & 70 m / min | ||||||||||

| Z - Axis | 90 mm & 40 m / min | ||||||||||

| V - Axis | 1200 mm & 80 m / min | ||||||||||

| W - Axis | 100 mm & 40 m / min | ||||||||||

| A - Axis | 1260 mm & 35 m / min | ||||||||||

| Boring unit : | Vertical drilling bit - top | 12 = 7 (X Axis) + 5 (Y Axis) | |||||||||

| Vertical drilling bit - bottom | 9 | ||||||||||

| Horizontal drilling bit | 2 (Left) + 2 (Right) and 2 (Front) + 2 (Back) | ||||||||||

| Motor power | 2.2 kw (3 hp) | ||||||||||

| Routing unit spindle x 2 : | Router spindle power | 3.5 kw (5 hp) | |||||||||

| Spindle speed | 2/18000 rpm | ||||||||||

| Other specifications : | Working table height | 1020 mm | |||||||||

| Air pressure | 6 to 8 kg / cm² | ||||||||||

| Total power | 19.2 kw (25.5 hp) | ||||||||||

| Machine dimensions L x B x H | 6700 x 2900 x 2450mm | ||||||||||

| Approx. net weight | 2500kg | ||||||||||