Redefining Panel Processing Technology

Redefining Panel Processing Technology

Redefining Panel Processing Technology

Redefining Panel Processing Technology

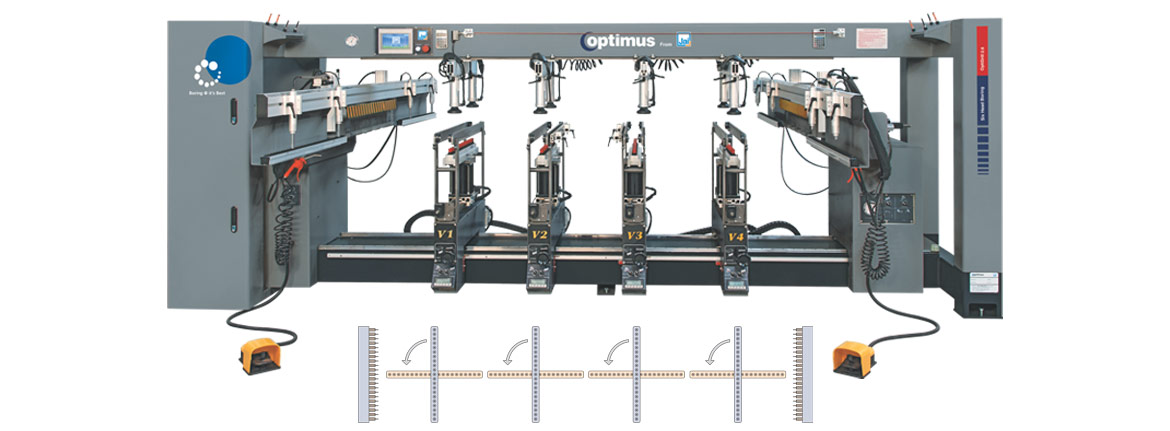

Length wise movement of heavy duty precision vertical boring heads on heavy linear rolling guides for a prompt & easy positioning with digital readout.

The all four vertical heads can slide away from each other depending on the center distance required between them. They can also be rotated by 90° giving more locational positioning.

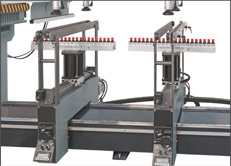

The Aluminum fence with support rollers has four reference stops that slides smoothly for smooth positioning. This makes it easy to feed long workpieces. Second vertical head assembly has also reference stopper for perfect side position alignment of longer workpiece.

Quick adjustment & easy setting of horizontal boring head unit. Boring depth can be also easily adjustable. Unit has pneumatically operated solid clamp for proper clamping of work piece at front end during boring process.

User friendly Smart Touch PLC Control Panel.

| Model | Unit |

OptiDrill 2.6 |

| Maximum working thickness | mm |

60 |

| Maximum size of work piece | mm |

2500 x 640 |

| Number of spindle head | no. |

Six (Two Horizontal & Four Vertical) |

| Number of spindle head | no. |

21 |

| Total spindles | nos. |

21*6 = 126 |

| Shank diameter of drill | mm |

10 |

| Spindle rotation speed | rpm |

2800 |

| Maximum drilling diameter | mm |

32 |

| Drilling depth | mm |

0 ~ 50 (drill length 70 mm) |

| Compressed air required | Kg / cm² |

6 to 8 |

| Electric motor - 3 phase | hp |

6 no's x 2 hp = 12 |

| Machine dimension (L x B x H) | mm |

4400 x 3050 x 1650 |

| Approx. net weight | kg |

1700 |