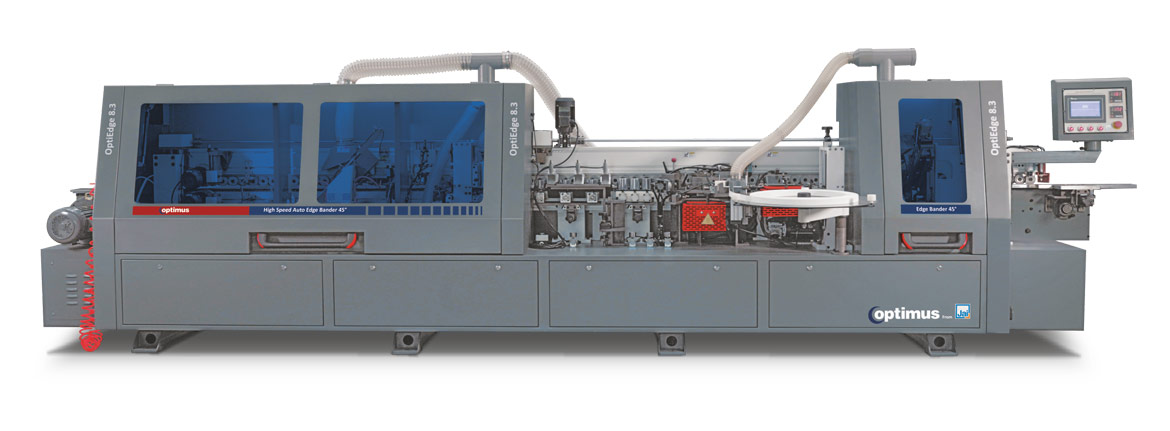

Redefining Panel Processing Technology

Redefining Panel Processing Technology

Redefining Panel Processing Technology

Redefining Panel Processing Technology

![]()

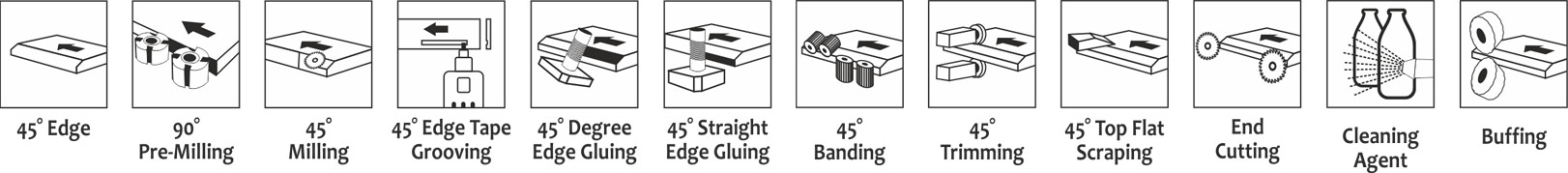

90° Pre - Milling

An optimal unit for panel edge pre-milling with two heavy duty high frequency motors supplied with set of diamond cutters, as standard supply with machine.

![]()

45° Milling

An optimal unit to make panel edge 45°, with 5 hp heavy duty high frequency motor in single pass.

![]()

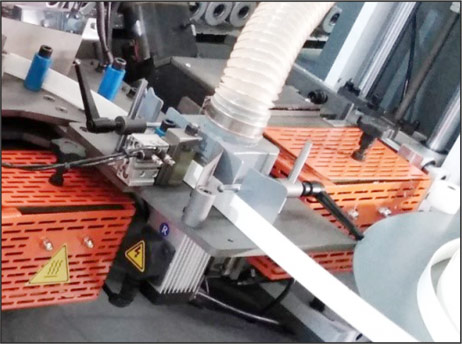

45° Edge Tape Grooving

An optimal unit for edge tape grooving to make proper banding with panel with diamond groove cutter, as standard supply with machine.

![]()

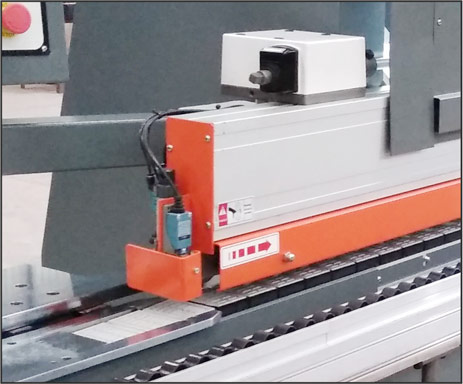

The Feed Track

Robust feed chain & conveyor system with heavy duty gearbox gives straight movement effective pressure on small / big panels.

![]()

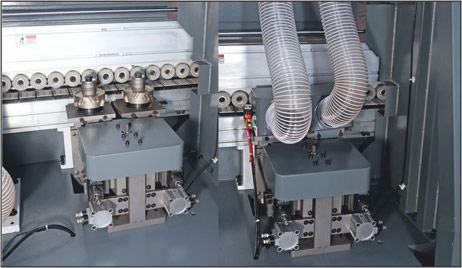

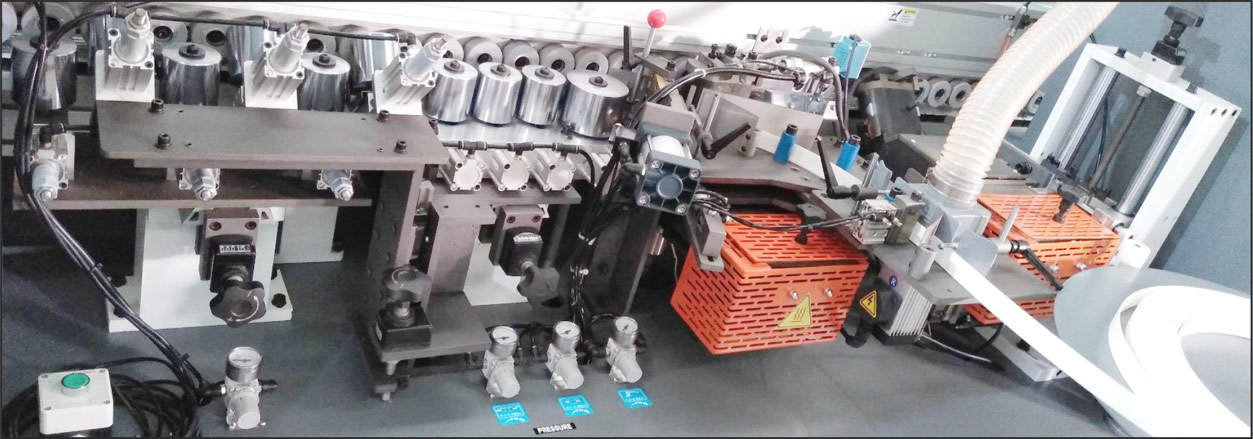

45 Degree & Straight Edge (below degree edge) Gluing, Banding & Edge Cutting :

Independent twin glue tanks apply the glue to the degree edge and straight edge(below degree edge) of degree panel. Both glue spreading roller provides precise & consistent glue application.

Perfect adhesion to the applied edge with heavy duty pressure rollers.

There are groups of pressure rollers for proper adhesion on inclined edge and also on the straight edge of degree panel.

Heavy duty knife with pneumatic pressure cuts the edge banding materials smoothly up to 25 mm height & 2 mm thickness.

![]()

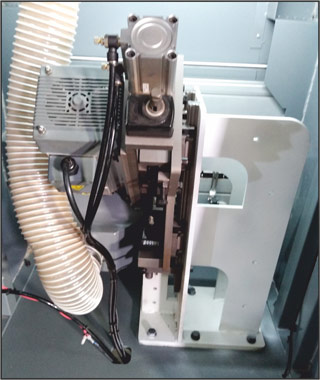

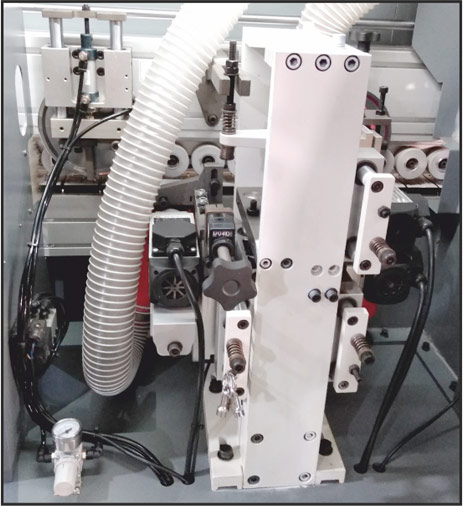

45° Trimming

Compact and powerful high frequency two motors guarantees perfect finish on edge. High level finishing thanks to the sturdy & heavy duty structure which is free of any vibration. Trimmer cutter trims the perfect finishing on straight edge of panel.

45° Top Flat Scrapping

Gives the best finishing touch to the PVC/ABS edges, leaving no trimming marks on the panel. Unit complete with rotating copiers.

![]()

End Cutting

Compact and powerful high frequency two motors guarantees perfect finish on edge, sliding on two prismatic heavy guideways with recirculation ball bearings.

![]()

Cleaning Agent

In order to prevent glue to adhere on panel, cleaning liquid is sprayed to lower & upper edge surface of the panel.

![]()

Buffing

Perfect straight & degree edge banding finishing by dual unit. Independently adjustable buffing wheels, for cleaning & polishing of the panel. It can be adjustable at a particular angle to maximize its effect for perfect finishing of workpiece & increase the life of buffing wheels.

![]()

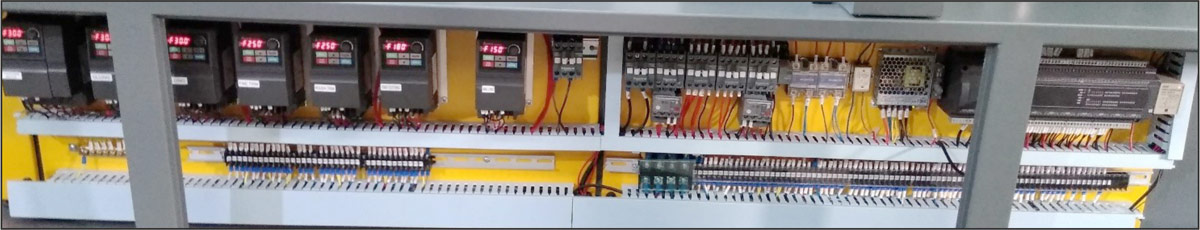

Control Panel

Easy accessible user friendly Smart Touch PLC control panel positioned at machine in-feed, for easy & quick operations.

![]()

Pressure Beam Up-down

Motorized up-down movement of pressure beam for easy panel thickness setting for quick operation from control panel.

![]()

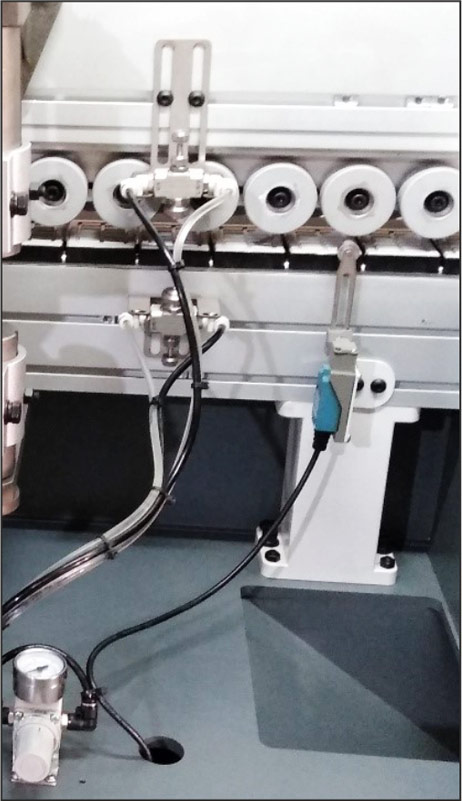

Auto Lubrication

Automatic lubrication system circulates lubrication to the required parts of the machine, ensures efficient operation and increase life of parts.

All electrical & electronics components are well known international reputed brands for trouble free performance.

| Model | Unit |

OptiEdge 8.3 |

Only 45° |

||

| Work piece thickness range | ||

| - Inclined 45° edge | mm |

12 - 25 |

| Minimum workpiece width | mm |

120 |

| Minimum workpiece length | mm |

250 |

| Edge banding thickness for PVC & ABS in coil form | ||

| - Inclined 45° edge | mm |

0.4 - 2.0 |

| Work piece feeding speed | m / min |

12 |

| Pre-milling motor power | no / hp |

2 x 3 |

| 45° milling motor power | no/hp |

1 x 5 |

| Trimming motor power | no/hp |

2 x 1 |

| End cutting motor power | no/hp |

2 x 0.5 |

| Buffing motor power | no/hp |

2 x 0.5 |

| Air pressure required | kg/cm2 |

6 to 8 |

| Working temperature range | °C |

180 - 200 |

| Glue pot capacity | kg |

2.0 |

| Total power | hp |

30.5 |

| Machine dimension (L x B x H) | mm |

7100 x 1530 x 1600 |

| Approx. net weight | kg |

2400 |