Redefining Panel Processing Technology

Redefining Panel Processing Technology

Redefining Panel Processing Technology

Redefining Panel Processing Technology

Model OptiRout 9.0 (L-ATC) CNC Router without boring also available

Precision 9V Spindle Vertical Boring Head for drilling

9 kw Heavy duty ATC Spindle

Rotary type 12 position auto tool changer reducing time

For Model: OptiRout 9.9V (R-ATC)

Linear type 8 position auto tool changer reducing time

(Model: OptiRout 9.0 (L-ATC)

Heavy Duty Linear Rail & rack & pinion for high cutting speed and accuracy

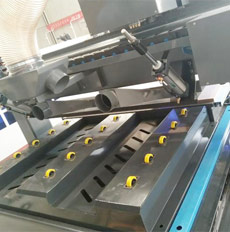

Double layer Nesting table for an efficient and secure hold of work piece

Effective dust cleaning system support rollers

Reference stops for proper alignment of panel

Heavy Duty Servo Motors with Shimpo Reducer

Bigger safety spindle covers for effective dust collecting and safety

Automatic lubrication system for smooth all three axis linear guide

| Model | OptiRout 9.0 (L- ATC) |

OptiRout 9.9V - ATC |

| X - Y - Z Axis working area | 1300 x 2500 x 200 mm | 1300 x 2500 x 200 mm |

| Resolutions | 0.0025 mm | 0.0025 mm |

| X - Y movement | Rack & pinion gear drive / Taiwan | Rack & pinion gear drive / Taiwan |

| Z movement | Heavy ball screw / TBI | Heavy ball screw / TBI |

| Guide | Linear guide 30 mm - Taiwan for X & Y Axis | Linear guide 30 mm - Taiwan for X & Y Axis |

| Linear guide 25 mm - Taiwan for Z Axis | Linear guide 25 mm - Taiwan for Z Axis | |

| Spindle | 9 kw, ATC Air-cooled Spindle / 18000 rpm | 9 kw, ATC Air-cooled Spindle / 18000 rpm |

| Boring head & power | n/a | 9V Boring head (5 + 4) / 1.5 kw |

| Tool magazine type | Linear type with 8 tools holder | Rotary type with 12 tools holder |

| Controller & drive motors | WEIHONG with Servo motors & shimpo reducer | WEIHONG with Servo motors & shimpo reducer |

| Working voltage | AC 380 V / 50 Hz, 3 Ø | AC 380 V / 50 Hz, 3 Ø |

| Command code | G code | G code |

| Collet type & size | ER32 (6, 8 mm) | ER32 (6, 8 mm) |

| Compatible software | Art Cam, Alfa Cam | Art Cam, Alfa Cam |

| Oil lubrication system | Standard | Standard |

| Vacuum table & pump | Standard with 7.5 kw air type pump | Standard with 7.5 kw air type pump |

| Machine dimension (L x B x H) | 4200 x 3400 x 2450 mm | 4200 x 3400 x 2450 mm |

| Approx. net weight | 2800 kg | 2700 kg |

Automatic loading / unloading system enable significant increases in productivity